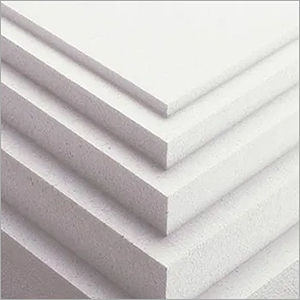

Thermocol Mould

700.00 - 2000.00 INR/Meter

Product Details:

X

Thermocol Mould Price And Quantity

- 700.00 - 2000.00 INR/Meter

- 14 Meter

Thermocol Mould Trade Information

- 10000 Meter Per Day

- 2-3 Days

- Delhi Haryana

Product Description

Thermocol Mould is a packaging material that is well-designed and manufactured in our state of the art production division with the help of cutting-edge tools and techniques. Thermocol is a lightweight and sturdy material. It is used mainly in packaging applications as the thermocol can endure impacts, shock, and shear forces. Therefore, it provides the utmost protection against such degrading factors. Clients can approach us to purchase the Thermocol Mould in varied sizes and types and that too at a cost-effective price.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email